DYNAMIC TTX – PREMIUM AUTOMATION

Mach 1’s DYNAMIC automatic stretch packaging systems are the perfect solution for higher production rates with around the the clock operation. These conveyorized systems can be customized and implemented as stand alone or in-line with endless configuration possibilities. Our engineering capabilities can provide an infinite list of optional features for specific applications or load types. With quality components and heavy duty construction, the DYNAMIC line of automated systems is your ultimate solution for long term reliability and lowest cost of operation.

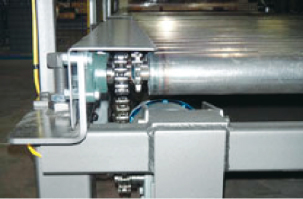

HEAVY DUTY CONVEYORS

Conveyors that come standard on Mach 1 automatic systems are built in-house from the strongest materials and quality components. Expect frames built with heavy gauge and structural steel, fully welded conveyor rollers with solid steel axels and cast-iron flanged bearing support. Our fabricating techniques have been developed to provide tightly assembled conveyor rollers with side-to-side play.

ROBUST ENGINEERING

We are the company known for heavy duty, stable and long lasting machinery. This comes as no surprise when all of our engineering relies on structural steel and precision laser cut steel components. Oversized mechanical components combined with smart technologies contribute to the lowest maintenance requirements in the industry.

250% FILM PRE-STRETCH

Often described as the “heart” of a stretch wrap system, the X-Stretch 250% pre-stretch film carriage is what sets apart Mach 1 expertise from the rest of the pack. The most powerful pre-stretch film carriage in the industry, the X-stretch is an advanced combination of technology and all-steel components that provides the best film feed control with smooth and consistent delivery. The system also features oversized bearings, chain/sprocket roller drive and precision machined pre-stretch rollers.

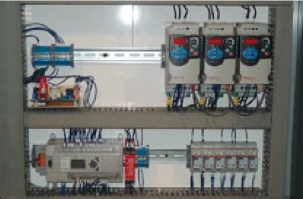

CONTROL PANEL

The ALLEN-BRADLEY controller (PLC) and touch screen are paired to provide the most intelligent and intuitive operator interface. All system functions can be calibrated on the touch screen and critical parameters are password protected. Every AC motor, including conveyor motors, has a dedicated ALLEN-BRADLEY drive for a smoother operation and more flexible settings.

LOAD SPECIFICATIONS |

|

|---|---|

| Max. Load Size | 48″ x 48″ Standard Larger Optional |

| Max. Load Height | 84″ Standard, Up to 110″ Optional |

| Max. Load Weight | 5,000 lbs Standard, 6,000 lbs Optional |

| Production Capacity | Up to 45 loads per hour |

FILM PRE-STRETCH FEATURES |

|

|---|---|

| Power 250% film Pre-Stretch | Standard |

| Film Capacity | 20″ Standard, 30″ Optional |

| No Contact Film Tension Sensor | Standard |

| Corner Compensation | Automatic, X-Stretch system |

| Easy Thread Film Threading | Standard |

MACHINE FEATURES |

|

|---|---|

| Arm / Turntable speed | Up to 16 |

| Arm Brake | N/A |

| Arm Support | N/A |

| Turntable Home Position Lock | Standard |

| Film Carriage Drive | Single Chain |

| Short Load Capabale | Standard (12″ min.) |

| Hot Plate Film Cutter | Standard |

| Standard Voltage | 240 VAC / 3 ph / 60 Hz |

| Standard Air | 4 CFM @ 80 PSI |

CONVEYOR FEATURES |

|

|---|---|

| Roller Spacing | 3.5″ Standard, 2.75″ Optional |

| Roller Bearing Type | Ball Bearing with Cast Iron Bolt-on Flage |

| Between Frame width (BFR) | 52″ |

| Top Of Roller Height | 18″ Standard, Other Optional |

| Conveyor speed | Adjustable 20 to 60 FPM |

CONTROL FEATURES |

|

|---|---|

| Micro controller | Allen Bradley MicroLogix |

| Touch Screen interface | Allen Bradley PanelView 600 plusl |

| Motor Control | Allen Bradley PowerFlex |

| Control Panel Cabinet | NEMA12 |

| System modes | Manual, Automatic, Automatic Pass Through |

| Film force control | Adjustable, Automatic Tension Release at Beginning and End of Cycle |

| Independent Top / Bottom Wrap Count | Standard |

| Independent Film Up / Down Speed | Standard |

| Manual Wrapper Controls | Standard |

| Manual Conveyor Forward / Reverse Jog | Standard |

| Conveyor Speed Adjustable | Standard |